- Home

- Free Samples

- Premium Essays

- Editing Services

- Extra Tools

- Essay Writing Help

- About Us

2500 - Essay Example

The stability can be defined in two…

- Subject: Miscellaneous

- Type: Essay

- Level: Undergraduate

- Pages: 4 (1000 words)

- Downloads: 0

- Author: tmayer

Extract of sample "2500"

The function of the frame is twin fold, as it needs to be static as well as dynamic. The static as the term means is the function of the frame or the chassis of the motorcycle to remain well balanced, while taking the load of the whole motorcycle machine and its driver. Dynamic function is more related to the role of the frame in driving conditions, as the chassis in conjunction with the steering rod and suspension devices etc. must result in accurate steering and handling of the road bumps, and proper steering, particularly while negotiating the corners.

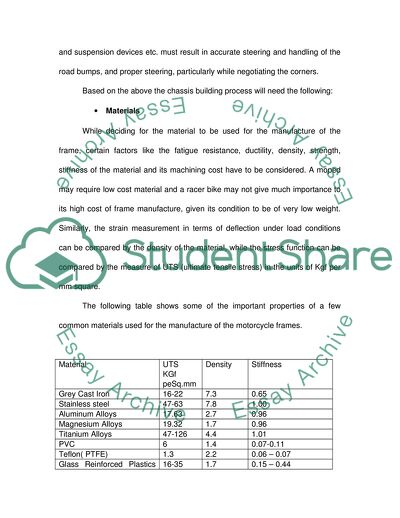

While deciding for the material to be used for the manufacture of the frame, certain factors like the fatigue resistance, ductility, density, strength, stiffness of the material and its machining cost have to be considered. A moped may require low cost material and a racer bike may not give much importance to its high cost of frame manufacture, given its condition to be of very low weight. Similarly, the strain measurement in terms of deflection under load conditions can be compared by the density of the material, while the stress function can be compared by the measure of UTS (ultimate tensile stress) in the units of Kgf per mm square.

While all the above material is suitable for the chassis building, the exact requirement has to be decided keeping in view the volume of production, its cost and the parameters given in the above table. Although the aluminum frame structure will need tubing of almost double the diameter of steel tubing, the aluminum tube weight will be still lesser. Hence keeping the cost and other parameters in view the material needs to be selected depending on the duct ability and density of the material, as mostly tubes, beams and the sections will be required for the chassis manufacture.

However, the most popular material for this purpose is the steel in the shape of a tube or a sheet.

...Download file to see next pages Read MoreCHECK THESE SAMPLES OF 2500

Managing Financial Resoures and Decisions 4. Answer 13 questions.No more than 2500 words allowed

Elemental Cost Plan for Commercial Office Development

Personal Finance Concepts And Other

Conditions for the Redemption of Shares

Issues in Finance and Accounting

Principles of Econometrics

Financial Plan for a Retail Store Selling

The Managerial Accounting

- TERMS & CONDITIONS

- PRIVACY POLICY

- COOKIES POLICY