- Home

- Free Samples

- Premium Essays

- Editing Services

- Extra Tools

- Essay Writing Help

- About Us

- Studentshare

- Subjects

- Miscellaneous

- Supply chain managment

Supply chain managment - Essay Example

- Subject: Miscellaneous

- Type: Essay

- Level: Undergraduate

- Pages: 4 (1000 words)

- Downloads: 0

- Author: stoltenbergted

Extract of sample "Supply chain managment"

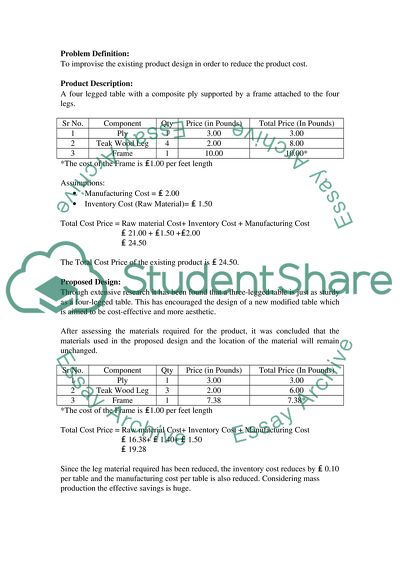

achieve maximum efficiency a company has to incorporate the supply chain in the design stage of a product as any change in the later stages of the product will entail huge expenses due to redesigning. This report describes in brief how supply chain is incorporated in deign. The report uses an example of a regular four legged wooden table and explains how the supply chain concept has helped find a more improved method of designing a product thereby reducing the manufacturing costs, lead time and inventory costs.

Through extensive research it has been found that a three-legged table is just as sturdy as a four-legged table. This has encouraged the design of a new modified table which is aimed to be cost-effective and more aesthetic. Since the leg material required has been reduced, the inventory cost reduces by ₤ 0.10 per table and the manufacturing cost per table is also reduced. Considering mass production the effective savings is huge. The supply chain concept has been incorporated in the design of the proposed product.

According to Cargille & Bliss (2001), the metrics to gauge the performance include the quality of the product, development time, and low material cost. The product has been designed bearing in mind the procurement of raw material in order to reduce the material cost. The material in this case remains unchanged but the quantity is reduced bringing down the material cost. With the raw materials unchanged, the need to negotiate the price of the raw materials does not arise. However if the company chooses to collaborate with the suppliers to provide the required quantity at the right time, the company can benefit by reducing its holding cost which includes warehousing, shrinkage, opportunity cost tied up with inventory (2001).

The trade-off between material cost and inventory holding costs is made when choosing between a supplier offering a shorter delivery time but higher material price and one offering lower material price but longer

...Download file to see next pages Read More

- TERMS & CONDITIONS

- PRIVACY POLICY

- COOKIES POLICY