StudentShare

Our website is a unique platform where students can share their papers in a matter of giving an example of the work to be done. If you find papers

matching your topic, you may use them only as an example of work. This is 100% legal. You may not submit downloaded papers as your own, that is cheating. Also you

should remember, that this work was alredy submitted once by a student who originally wrote it.

Login

Create an Account

The service is 100% legal

- Home

- Free Samples

- Premium Essays

- Editing Services

- Extra Tools

- Essay Writing Help

- About Us

✕

- Studentshare

- Subjects

- Health Sciences & Medicine

- Aspirin Reformulation Process

Free

Aspirin Reformulation Process - Report Example

Summary

The "Aspirin Reformulation Process" paper describes the selection of various formulations as well as pharmaceutical manufacturing attributes. The report also emphasises the use of a risk-based approach, considering the same in the control strategy in the aspirin reformulation process…

Download full paper File format: .doc, available for editing

GRAB THE BEST PAPER96.4% of users find it useful

- Subject: Health Sciences & Medicine

- Type: Report

- Level: Undergraduate

- Pages: 13 (3250 words)

- Downloads: 0

- Author: morargarrick

Extract of sample "Aspirin Reformulation Process"

Product Formulation Report Executive Summary This report is intended to present an all-inclusive discussion of aspirin reformulation process. Using ascientific approach to the formulation of aspirin tablets, this report aims to identify the key performance attributes required to be followed in order to impart the medication process successfully. Correspondingly, a profile of the target product, i.e. Aspirin, will be provided initially, as the report proceeds to describe the selection of various formulation as well as pharmaceutical manufacturing attributes. Along with the scientific approach, the report will also emphasise the use of a risk-based approach, considering the same in the control strategy in the aspirin reformulation process. Grounded on these two approaches, various dimensions of manufacturing process development will be highlighted, followed by container closure system, microbiological attributes, manufacturing procedure, critical steps as well as intermediates for aspirin tablets. To be noted in this regard, the rationale behind reformulating the target product (i.e. Aspirin) is to ensure most cost effective healthcare facility to the European market as well as to develop the new formula as a more stable one in comparison with the traditional formula.

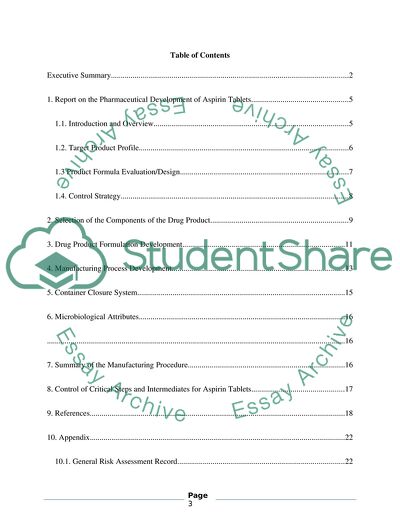

Table of Contents

Executive Summary 2

1. Report on the Pharmaceutical Development of Aspirin Tablets 4

1.1. Introduction and Overview 4

1.2. Target Product Profile 5

1.3 Product Formula Evaluation/Design 6

1.4. Control Strategy 7

2. Selection of the Components of the Drug Product 8

3. Drug Product Formulation Development 10

4. Manufacturing Process Development 12

5. Container Closure System 14

6. Microbiological Attributes 15

15

7. Summary of the Manufacturing Procedure 15

8. Control of Critical Steps and Intermediates for Aspirin Tablets 16

9. References 17

10. Appendix 21

10.1. General Risk Assessment Record 21

10.2. Hazardous and Dangerous Substances Risk Assessment (COSHH/DSEAR) 22

1. Report on the Pharmaceutical Development of Aspirin Tablets

1.1. Introduction and Overview

Researches based on the formulation of aspirin tablets have agreed that it has one active ingredient, i.e. acetylsalicylic acid and a range of options available for use as excipients such as aerosol, lactose and cornstarch (Erum & et. al., 2011). It also has a dispersible formulation, which makes it easy to be administered to children, making changes in its desired dosage. However, it also possesses certain limitations irrespective of having the advantage of being effective in several chronic conditions (Aspirin Foundation, n.d.). To be specific, experiments and prior observations have revealed that aspirin will have an adverse effect on patients who are allergic, have the problem of bleeding disorder, asthma or complain for bleeding ulcers in their stomach, as its active ingredient contains the properties that can cause gastrointestinal irritation. Among children, it is also observed to cause Reyes syndrome (MHRA, n.d.). As also supported by Erum & et. al. (2011), it is owing to these limitations that the formulation of aspirin needs a thorough research conducted on the possibilities of using lesser excipients aimed at the minimisation of its reactions.

1.2. Target Product Profile

Table 1: Target Product Profile

[Sources: (Gouthami & et. al., 2012); (US Pharmacopia, n.d.); (US Pharmacopia, n.d.)]

1.3 Product Formula Evaluation/Design

Aspirin, as can be commonly observed, has proved effective to give relief to the patients from extensive pain. As compared to other medical products, aspirin has an interesting history of invention, wherein with the passing years, developments in its formulation have been apparent (Gurbel & et. al., 2007; Elwood & et. al., 1974). Through continuous research, more and more information has been obtained about the old formulation of aspirin (C9H8O4). As mentioned in Diener & et. al. (1996), the base element used in the formulation of aspirin is salicylic acid (C7H6O3). According to the commonly used formula to produce aspirin from salicylic acid, acetic anhydride (C4H6O3) is used. Following chemical reaction with each other, i.e. between C7H6O3 and (CH3CO)2O, wherein the former produces the compounds of the phenol hydroxyl group and the latter produces the acetyl group, an esterification of the two elements takes place, resulting in Aspirin. As a by-product, this chemical reaction also produces acetic acid (C2H4O2). In this formula, 85% phosphoric acid is used as a catalyst (Rainsford, 2004). Hence, the old formula followed when producing aspirin can be documented as follows.

C7H6O3 + C4H6O3 C9H8O4 + C2H4O2

However, this formula possesses certain drawbacks. According to López-Farré & et. al. (1995), the acylating agent C4H6O3, is regarded as a weak ingredient and is neither cheap nor readily available for easy production of aspirin. It causes skin irritation and it is considered as volatile as well, as revealed in Hargrove-Huttel & Colgrove (2008), Hankey & et. al. (2000) and Chamberlain (1979). From a critical point of view, it can thus be argued that it is primarily because of the chemical properties of acetic anhydride that patients on regular aspirin dosage often complain of skin irritation and similar other problems as stated in Aspirin Foundation (n.d.). To reduce this side effect of aspirin, this agent will be replaced with acetyl chloride (C2OH3Cl) in the new formula. It is also expected that this agent will be helpful in producing aspirin at a cheaper price, making it easily affordable for patients. Observably, C2OH3Cl is a stronger acylating agent than C4H6O3. It also has a characteristic to burn in the air, having minimal influence on the created aspirin compounds. However, in reaction with salicylic acid, it produces hydrogen chloride (HCl) as the by-product. To neutralise this by-product, pyridine will be used, which has the property of a catalyst as well. Hence, the new formula for producing aspirin can be noted as:

C7H6O3 + C2OH3Cl C9H8O4 + HCl

1.4. Control Strategy

Study shows that salicylic acid can be acutely toxic and irritating to various parts of the human body owing to which, effective control measures need to be taken when performing the above-described formula. In case the irritant affects the eyes, it is advisable that the eyes be flushed repeatedly with a generous amount of water, continuously upto 15 minutes. It is also necessary to lift the eyelids, both upper and lower, when washing, to gain relief from the irritation. In case of skin irritation, it is advisable that the affected individual washes the area with abundance of water and soap for approximately 15 minutes, removes wearable which were also contaminated and seeks medical assistance at the earliest. Salicylic acid can also cause irritation and toxicity through inhalation. In such circumstances, immediate response will be necessary by taking the person in open air and providing artificial respiration if non-responsive and is not breathing. Another important ingredient used for this formula is acetyl chloride (ethanol). Being affected due to exposure to ethanol, the affected area should be washed with water for at least 15 minutes; while in case of inhalation, the individual should drink water or milk (refer to pro-forma 6). Again, in case an individual is exposed to HCl, it is also recommended that immediate medical assistance should be sought. Similar to salicylic acid, HCl contact with eyes or skin should follow rinsing the area with plentiful amount of water (Rowe & et. al., 2009; Weyerhaeuser, 2008). However, considering the risk factors associated with the recreated formula for the target product, measures will be taken to test product effectiveness and its adverse effects. In order to test these risk factors, laboratory examinations in controlled environment will be undertaken periodically. This will also help in the regular monitoring of the product’s integrity and quality. In case the formula is observed to have serious adverse effects, necessary measures will be taken before its ultimate launch in the market.

2. Selection of the Components of the Drug Product

Investigations to reformulate aspirin, as per the objective taken in this project, began with the assessment of the chemical properties possessed by the two components, viz. Acetyl chloride (C2OH3Cl) and Pyridine, in replacement of Acetic anhydride (CH3CO)2O) and 85% Phosphoric acid respectively. To be mentioned in this context, Acetyl chloride was identified to be comparatively more vigorous than Acetic anhydride and thus, to produce the same quantity of aspirin, the requirements of this ingredient will be lesser. In addition, because this particular ingredient is readily available in the market at a comparatively cheaper rate, it will make the product process of aspirin more cost effective. Likewise, price for the medicine can be reduced and offered to the consumers in larger quantities at cheaper rates. Using Acetic chloride as a replacement of Acetic anhydride will produce HCl reacting with Salicylic acid. Correspondingly, 85% Phosphoric acid was replaced with Pyridine, which gave an added benefit being a catalyst as well as a neutraliser to the produced HCl in the reaction.

It is worth mentioning in this regard that the cost advantages offered by the new formulation of aspirin shall be much effective in the European market, wherein the medicine has been available at high prices, often double or quadruple to its price in other continents. Responsively, studies such as Greving & et. al. (2008) and Drummond & et. al. (2002) revealed that Aspirin treatment in Europe is highly expensive. According to Greving & et. al. (2008), aspirin is a preferred secondary treatment solution to cardiovascular risks to patients and hence, has been much in demand in the European market over the past decades, similar to other continents. However, its excessive cost in the market has raised grave concerns regarding its positive results on the treatment procedure, i.e. on its cost-benefit aspects (Refer to table 2). Hence, the production of aspirin with the new formula shall make it more cheaply available in the European market, positively affecting the cost-benefit aspects associated with treatment with aspirin tablets.

Table 2: Sensitivity Analyses of Aspirin Costs and Results

[Source: Greving & et. al. (2008)]

3. Drug Product Formulation Development

As already mentioned in the previous section, two ingredients have been replaced from the old formula of aspirin. While the old formula constituted Acetic anhydride and 85% Phosphoric acid, these two ingredients have been replaced with Acetyl chloride and Pyridine in the new formula. These two ingredients have been examined to offer better cost flexibility to the drug formulation process. To be mentioned in this context, the role of Acetyl chloride in the new formula developed is that of a ‘high quality acetylation agent’. It is fundamentally because its chemical properties make it a highly reacting agent when combined with salicylic acid, which is also able to produce irreversible reactions. Categorised in the group of organic acid chlorides, Acetyl chloride is known to be highly reactive. This particular ingredient is also classified in the group of acyl halides, which specifies its properties of being highly reactive with cold water (Lundblad, 2014). Subsequently, to its reaction with cold water, Acetyl chloride hydrolyses to form carboxylic acid. These chemical properties of Acetyl chloride become apparent in the case of its Nucleophilic Acyl Substitution reaction, which will be used in the new formulation. During the reaction process, HCl will be produced as the by-product, which will then be stabilised with the use of pyridine (MHHE, n.d.). Hence, pyridine has been used to stabilise the by-product (i.e. HCl) in the new formulation. To be noted in this purview, apart from pyridine, triethylamine could have also been used in the new formula. However, concerning the chemical properties of these two ingredients from a comparative perspective, it can be asserted that while pyridine is more soluble and stable than triethylamine, it was included in the formulation. Moreover, pyridine is examined as soluble in concentrated HCl, while triethylamine is found to be more reactive with special requirements for storage (Sandler & Karo, 1989). These properties of pyridine justify its need in the new drug formulation procedure, both as a catalyst as well as a neutraliser.

4. Manufacturing Process Development

The proposed new formula for aspirin, i.e. C7H6O3 (Salicylic acid) + C2OH3Cl (acetyl chloride) →Pyridine→ C9H8O4 (Aspirin) + HCl (hydrogen chloride), will be used to manufacture the target product portfolio, Aspirin. The target product will be produced in a tablet form for oral dosage. As per the new formulation method, 1 ml of Acetyl Chloride (C2OH3Cl) will be used for every 1 gram of salicylic acid in the manufacturing process of aspirin, following the new formulation process. To be noted in this context, the quantity required for the formulation of aspirin using Acetic anhydride (CH3CO)2O) was almost double the amount of Acetyl Chloride requirements for every 1 gram of salicylic acid. To be precise, in the new formulation procedure, a 1:1 ratio will be followed to produce aspirin from every 1 gram of salicylic acid. This particular property of the formulated process will not only add to the overall efficiency of the procedure to produce more aspirin, but will also limit the negative effects of the product, as was witnessed when using Acetic anhydride. In addition, the amount of Acetyl Chloride used in the manufacturing process is quite small to impose any critical effects to its consumption, which abides by the specifications of US Food and Drug Administration (FDA). Used in such a small amount also ensures purity of the produced aspirin. In general, acetyl chloride is examined to be poisonous when used in large quantities, owing to which the amount of this particular ingredient is maintained to be low in the new formulation process in order to ensure that the percentage use of this chemical is limited within the bar of maximum consumption by human. In the similar context, the amount specified for the use of acetyl chloride will also produce the required quantity of aspirin in reaction with the limiting agent, salicylic acid (refer to pro-forma 5).

However, on the other hand, to produce aspirin from 1 gram of salicylic acid and 1 ml acetyl chloride, 5 drops of pyridine will be required. The amount of pyridine required in this formulation process is evidently much higher than the amount of 85% Phosphoric acid required as per the old formula. Respectively, it should be mentioned that to neutralise the resulting hydrochloric acid, the amount of pyridine specified would be mandatory. To be noted in this context, lesser than the mentioned amount of pyridine is quite likely to fail to neutralise the by-product (i.e. HCl), produced during the reaction between the active agent and the limiting agent in the formula. Concerning the impacts of using many drops of pyridine, it can be asserted that because pyridine is weakly reactive but a strong catalyst, it will help pacing the reaction without any influence on the target product, thereby ensuring its purity. On the contrary, in the old formula, because 85% Phosphoric acid is much reactive, its quantity was limited, which in turn affected its catalyst qualities to help the target product to crystallise. It is owing to these concerns that as replacement of 1 drop of 85% Phosphoric acid, 5 drops of Pyridine will be used in the new formula for the development of the target product, i.e. aspirin (refer to pro-forma 5).

When comparing the old formula with the new one, it can be observed that both the methods are dependent on the acetylation process of salicylic acid. One of the major differences observed in the two referred processes, i.e. the old formula and the new formula, is the obtainment of chloride ion as the leaving group of the new formula while the old formula resulted in a leaving group of acetate ion. In addition, the by-product obtained from both the formulae is also identified to be different, in respect that in the old formula the by-product obtained was acetic acid while the new formula produces HCl as the by-product (refer to pro-forma 5).

5. Container Closure System

The container closure system to be followed for the new formulated product, i.e. aspirin, will be based on the guidelines by the FDA. Undoubtedly, proper storage of aspirin is necessary to ensure its optimum result in the treatment procedure and likewise, to ensure its longevity. It is in this context that the tablets will be stored in High Density Polyethylene (HDPE) resin, which will be used as its materials of construction. To be noted, aspirin tablets are quite prone to damage owing to heat and extreme moisture. Thus, to reduce the effects of heat on the tablets and prevent excess moisture from entering the package, the product will be offered in a closure system, constituting two packaging components, i.e. primary component and secondary component. The secondary package component to be used for the packaging of aspirin will be made of High Density Polyethylene (HDPE) resin bottles as already mentioned. These containers will be packaged with ‘container inner seals’ and closure liners, which can be defined as the primary package components to be used in the containers holding aspirin. As per the FDA guidelines, the closure system of the container will use screw caps. To be noted in this context, packaging of aspirin shall be subjected to the guidelines specified as per the 16 CFR 1700-1702 - Special Packaging code. In accordance with this particular principle, the Poison Prevention Packaging Act of 1970 will be applicable (Center for Drug Evaluation and Research (CDER), 1999). Hence, ensuring a proper container closure system will be essential for the target product, i.e. aspirin. A demonstration of the container for the produced aspirin has been illustrated in the below diagram:

6. Microbiological Attributes

Considering the chemical properties of aspirin, it can be identified that microbiological attributes may impose strong effects on the therapeutic use of the tablets, if not contained in an appropriate manner, i.e. away from heat and excess moisture. To be mentioned in this regard, aspirin is considered as a weak acid and lacks solubility in cold water. However, persistence of heat and moisture in the air is quite likely to damage the tablets subjected to its appropriate storage. However, it is widely accepted that aspirin acts as a strong antibacterial component. This in turn limits the risks faced by aspirin tablets of getting affected due to microbiological attributes largely. Nevertheless, storing the tablets in a cold and dry place will be essential to preserve the longevity and usability of the product.

7. Summary of the Manufacturing Procedure

The intention of the manufacturing process was to reformulate aspirin tablets, with an objective to make this widely usable medicine available in the European market at a cheaper rate. In the process, various limitations associated with the old formula was identified, which were step-by-step addressed and a new formula was developed that used Acetyl Chloride (C2OH3Cl) instead of Acetic anhydride (CH3CO)2O) and Pyridine instead of 85% Phosphoric acid, to produce aspirin tablets. While the two formulae remain similar on many attributes, the new formula was observed to produce better quantity of aspirin in a cost-effective way, without affecting the industry standards on the quality measures of the same. To be noted, the manufacturing process has remained adequately concerned about the control measures to be applied in order to preserve safety of the lab-technicians, when using hazardous materials.

8. Control of Critical Steps and Intermediates for Aspirin Tablets

The manufacturing process undertaken to produce aspirin products followed critical steps to ensure proper control measures. To be mentioned in this regard, control and safety measures have been designed on the basis of the hazardous nature of every ingredient used and produced in the manufacturing process. Accordingly, risk analysis of every material has been assessed from a comparative view, concerning the differences persisting amid the old and the new formulae. Due consideration has also be rendered on the size, shape and colour of the tablets and the packaging system as per the mentioned guidelines of FDA.

9. References

Aspirin Foundation, No Date. What is Aspirin. Chemistry. [Online] Available at: http://www.aspirin-foundation.com/what/chemistry.html [Accessed June 29, 2014].

Chamberlain, J. P., 1979. Fluorographic Detection of Radioactivity in Polyacrylamide Gels

with the Water-Soluble Fluor, Sodium Salicylatele. Analytical Biochemistry, Vol. 98, pp. 132-135.

Center for Drug Evaluation and Research (CDER), 1999. Guidance for Industry: Container Closure Systems for Packaging Human Drugs and Biologics. Chemistry, Manufacturing, and Controls Documentation. [Online] Available at: http://www.fda.gov/downloads/Drugs/Guidances/ucm070551.pdf [Accessed June 29, 2014].

Diener, H. C. & et. al., 1996. European Stroke Prevention Study 2. Dipyridamole and Acetylsalicyclic Acid in the Secondary Prevention of Stroke. Journal of the Neurological Sciences, Vol. 143, pp. 1-13.

Drummond, S. & et. al., 2002. Cost of Aspirin and Satins in General Practice. Quarterly Journal of Medicine, Vol. 95, pp. 23-26.

Elwood, P. C. & et. al., 1974. A Randomized Controlled Trial of Acetyl Salicylic Acid in the Secondary Prevention of Mortality from Myocardial Infarction. British Medical Journal, Vol. 1, pp. 436-440.

Erum, S. & et. al., 2011. Formulation of Aspirin Tablets Using Fewer Excipients by Direct Compression. Pakistan Journal of Pharmacology, Vol. 28, No. 1, pp. 31-37.

Greving, J. P. & et. al., 2008. Cost-Effectiveness of Aspirin Treatment in the Primary Prevention of Cardiovascular Disease Events in Subgroups Based on Age, Gender, and Varying Cardiovascular Risk. Circulation, Vol. 117, pp. 2875-2883.

Gouthami, K. & et. al., 2012. Comparison Studies of Uncoated & Enteric Coated Aspirin Formulations. International Journal of Pharmacy, Vol. 2, No. 2, pp. 333-336.

Gurbel, P. A. & et. al., 2007. Evaluation of Dose-Related Effects of Aspirin on Platelet Function: Results From the Aspirin-Induced Platelet Effect (ASPECT) Study. American Heart Association, doi: 10.1161/CIRCULATIONAHA.106.675587.

Hankey, G. J. & et. al., 2000. Thienopyridines or Aspirin to Prevent Stroke and Other Serious Vascular Events in Patients at High Risk of Vascular Disease?: A Systematic Review of the Evidence From Randomized Trials. American Heart Association, doi: 10.1161/01.STR.31.7.1779.

Hargrove-Huttel, R. A. & Colgrove, K. C., 2008. Pharmacology Success: A Course Review Applying Critical Thinking to Test Taking. F.A. Davis.

López-Farré, A. & et. al., 1995. Effects of Aspirin on Platelet-Neutrophil Interactions

Role of Nitric Oxide and Endothelin-1. Circulation, Vol. 91, pp. 2080-2088.

Lundblad, R. L., 2014. Chemical Reagents for Protein Modification, Fourth Edition. CRC Press.

MHHE, No Date. Interconversion Reactions of Acyl Chlorides. Carboxylic Acid Derivatives. Nucleophilic Acyl Substitution. [Online] Available at: http://www.mhhe.com/physsci/chemistry/carey/student/olc/graphics/carey04oc/ref/ch20reactionsacylhalides.html [Accessed June 29, 2014].

MHRA, No Date. Aspirin 300mg Tablets Bp (Acetylsalicylic Acid). UPKAR. [Online] Available at: http://www.mhra.gov.uk/home/groups/l-unit1/documents/websiteresources/con2023336.pdf [Accessed June 29, 2014].

Rowe, R. C. & et. al., 2009. Handbook of Pharmaceutical Excipients: Sixth Edition. Pharmaceutical Press.

Rainsford, K. D., 2004. Aspirin and Related Drugs. CRC Press.

Sandler, S. R. & Karo, W., 1989. Organic Functional Group Preparations, Volume 3. Academic Press.

Santa Cruz, 2014. Material Safety Data Sheet. Sacylic Acid. [Online] Available at: http://datasheets.scbt.com/sc-203374.pdf [Accessed June 29, 2014].

SIGMA-ALDRICH, 2014. Material Safety Data Sheet. Version 3.8. [Online] Available at: http://www.nwmissouri.edu/naturalsciences/sds/a/Acetyl%20chloride.pdf [Accessed June 29, 2014].

U.S. Pharmacopia, No Date. Uniformity of Dosage Units. Pharmacopeial Forum, Vol. 30, No. 4, pp. 1474.

U.S. Pharmacopia, No Date. Aspirin Tablets. USP29-NF24 Page 200.

U.S. Environmental Protection Agency, 2009. Screening-Level Hazard Characterization: Pyridine and Pyridine Derivatives Category. Hazard Characterization Document. [Online] Available at: http://www.epa.gov/hpvis/hazchar/Category%20Pyr%20and%20Pyr%20Derivs_Sept2009.pdf [Accessed June 29, 2014].

Weyerhaeuser, 2008. Hydrochloric Acid. Material Safety Data Sheet. [Online] Available at: http://www.weyerhaeuser.com/pdfs/msds/454.pdf [Accessed June 29, 2014].

10. Appendix

10.1. General Risk Assessment Record

[Source: (Santa Cruz, 2014); (SIGMA-ALDRICH, 2014); (U.S. Environmental Protection Agency, 2009)]

10.2. Hazardous and Dangerous Substances Risk Assessment (COSHH/DSEAR)

1. Location of Process

2. Department

3. Assessment Ref.

4. Process (What is being done)

Reformulation of Aspirin

5. Frequency of use

6. Who is/are at risk?

—

7. Any special risk groups?

No

8. Substances and microbiological materials (include mixtures and products)

8a. Name

8b. Physical form

8c. Quantity handled

8d. Hazard pictograms (chemical, see foot of last page) and signal word (warning, danger or none)

or Hazard Group - HG1 or HG2 (microbiological)

8e. Workplace Exposure Limit (WEL) from EH40 / mg m-3, long (l) or short term (s)

8f. Control measures

8g. Disposal route

1 C7H6O3 (Salicylic acid)

Powder

2 grams

1. Eyes to be flushed with plentiful of water at least for 15 minutes after contact with salicylic acid

2. If in contact to skin, the area should be washed with soap and water for at least 15 minutes

3. Remove wearable immediately if in contact with the component

4. In case of inhalation, seek medical assistance and bring the affected to open air immediately

Distilled Water

2 C2OH3Cl (acetyl chloride)

Liquid

2 ml

1. Affected area should be washed with plenty of water for 15 minutes minimum

2. In case of inhalation, drinking milk or water will be essential besides seeking medical assistance to cure breathing troubles

Lab Bins or Plastic Containers

3 Pyridine

Liquid

5 drops

NA

Distilled Water

4 C9H8O4 (Aspirin)

Crystallised

—

—

NA

NA

5 HCl (hydrogen chloride)

Gaseous

—

1. Immediate medical assistance

2. Rinsing eyes and area of skin affected due to contact with HCl, with plentiful of water

Hydrolyze

9. Key Message

From the list above, what is the most dangerous/ hazardous substance and why?

From the list presented above, C2OH3Cl (acetyl chloride), which is also the limiting agent in the formula, can be identified as the most dangerous/hazardous substance, as it is flammable, corrosive in raw form and can be hazardous to health.

10. Instruction, training and supervision

10a. What special instructions are needed to carry out the process safely?

Using safety gears like gloves and masks during the manufacturing process

10b. What special training is required to carry out the process safely?

Adequate knowledge of the hazards associated with the use of the stated substances and understanding of their appropriate disposal route

10c. What supervision is required to carry out the process safely?

Monitoring by experienced lab-technician

11. Emergency measures for the process

11a. Minor spillage or release procedure

Wash with distilled water and collect the wiping cloth in lab bins

11b. Major spillage or release procedure

Wash with plenty of water

11c. Fire precautions and procedures

NA

11d. First aid precautions and procedures

Usage of plentiful of water and immediate assistance of medical professionals

12. Statement of approval (the process must only be approved if the estimated risk is trivial, low or moderate using the matrix at the end of this document)

Likelihood of harm occurring (L)

3

Severity of harm (S)

3

The risk arising from the process after applying the controls stated is (R = L x S)

9

12a. Assessed by [name(s) & signature(s)]

12b. Date

12c. Approved by (name and signature)

12d. Date

13. Is health surveillance required for personnel engaged in this process?

If yes, approver must notify Human Resources

Read

More

CHECK THESE SAMPLES OF Aspirin Reformulation Process

Importance of the Reformation in Europe

This research paper "Importance of the Reformation in Europe" shows that Western historiography has accumulated a broad scope of literature on the Reformation.... The history of the Reformation is a subject of many societies which are engaged in the history of religion and churches.... ... ... ... The history of the Reformation is a subject of many societies which are engaged in the history of religion and churches, as well as special public societies on the history of the Reformation in Germany and the U....

19 Pages

(4750 words)

Research Paper

Western Civilization (1300-1700): The Protestant Reformation

The Protestant Reformation is definitely one of the many events that took place during the Western Civilization.... This is a historical event that took place in the 16th-century.... It concerns the split within Western Christianity during the Western Civilization.... .... ... ... The Protestant Reformation is definitely one of the many events that took place during the Western Civilization....

6 Pages

(1500 words)

Term Paper

Reformation on the Modern World

Medieval view The medieval world view believed that the nature was an everlasting process and that it kept going from moment to moment by miracle which was new and renewed forever.... The process was also executed with the human being's absolute faith in God (Kobe)....

8 Pages

(2000 words)

Research Paper

Renaissance and Reformation

Renaissance and Reformation....

... The reformation period generally referred to as the protestant reformation, a period where there was a split in the Christians of the 16th century, completely shifting the course of Christianity in Europe.... ... ... ... Renaissance and Reformation....

... The reformation period generally referred to as the protestant reformation, a period where there was a split in the Christians of the 16th century, completely shifting the course of Christianity in Europe....

4 Pages

(1000 words)

Essay

The Research Application of PICO to Evidence Based Practice

Sex, Co-morbidity, race, age pathology (SCRAP)InterventionTesting and treatment appliedComparisonOther testing and treatment process reviewed as a controlOutcomeThe results of the experimentExample:For a 43-year-old man with gum disease, how does the effective application of doxycycline to alleviate gum bleeding compared to non-clinical intervention (i.... ith patients developing a requirement of more effective medical personnel, these trends in the planning and implementation process should be considered:1....

3 Pages

(750 words)

Coursework

Human Resource Strategy Formulation

Strategy formulation is a process of selecting the best activities in an organization which will lead to the realization of goals and objectives thereby achieving the organizations goals.... The process of strategy formulation is divided into various steps.... The strategy formulation process involves a lot of information which must be managed and organized well.... Strategy formulation process Gathering information Strategy formulation is a process of selecting the best activities in anorganization which will lead to the realization of goals and objectives thereby achieving the organizations goals....

1 Pages

(250 words)

Research Paper

Product Formulation Portfolio; Evaluation pro-forma 5 (PFPE5)

For example, the specified volume of acetyl chloride is small enough to ensure the purity of the aspirin produced.... Justification of new ingredient amount is it suitable for this formulation (for example some chemicals can only be used certain concentrations in human consumption products, see MHRA, FDA, EMEA or any scientific resources)

...

2 Pages

(500 words)

Essay

Christian Theology by Alison McGrath

This book review "'Christian Theology by Alison McGrath" discusses the fundamental elements of the Christian Faith.... The paper examines the core concepts and belief systems that form the basis of Christianity.... The paper then goes on to state the writer's personal beliefs.... ... ... ... The paper is written in two parts....

11 Pages

(2750 words)

Book Report/Review

sponsored ads

Save Your Time for More Important Things

Let us write or edit the report on your topic

"Aspirin Reformulation Process"

with a personal 20% discount.

GRAB THE BEST PAPER

✕

- TERMS & CONDITIONS

- PRIVACY POLICY

- COOKIES POLICY