- Home

- Free Samples

- Premium Essays

- Editing Services

- Extra Tools

- Essay Writing Help

- About Us

- Studentshare

- Subjects

- Miscellaneous

- Induction Motor

Induction Motor - Essay Example

- Subject: Miscellaneous

- Type: Essay

- Level: Masters

- Pages: 4 (1000 words)

- Downloads: 0

- Author: gunnar44

Extract of sample "Induction Motor"

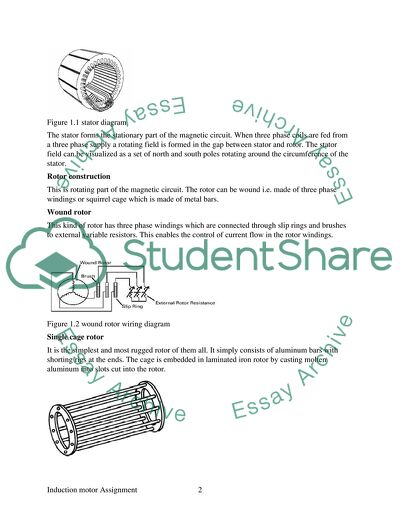

It is the simplest and most rugged rotor of them all. It simply consists of aluminum bars with shorting rigs at the ends. The cage is embedded in laminated iron rotor by casting molten aluminum into slots cut into the rotor. It is the simplest and inexpensive method of starting squirrel cage induction motors. In this case the motor is switched directly to supply voltage. However, the initial starting current is large usually about 5 to 7 times the rated current but starting current can be approximately 0.

75 to 2 times the full load torque. Therefore, to avoid large starting currents this method is restricted to small motors only This is achieved by connecting the motor to lower a voltage than rated voltage during starting thereby reducing starting torque and current and then increasing the stator voltage gradually after starting. One of the ways of achieving this is by use of autotransformer. The motor is connected permanently in delta or star but during starting it is switched first to a three phase tapped auto transformer and when it has accelerated almost top speed it is switched running position.

This kind of starting is used for wound rotor induction motors with slip rings. When the rotor circuit is added an external resistance any starting torque can be achieved up to the maximum torque. By cutting out the resistance gradually it is possible to maintain a high torque throughout the starting period. The external resistances will reduce the inrush starting current so that a starting torque in the range of 2 to 2.5 times the full load torque is obtained a starting current of 1 to 1.5 times the full load current.

Φ = Vs/Kmω where Km is a constant and depends on the number of turns of the stator winding. The range of speed control depends on the slip for maximum torque. This kind of control is suitable for constant torque load applications which need low starting torque and a narrow range

...Download file to see next pages Read More

- TERMS & CONDITIONS

- PRIVACY POLICY

- COOKIES POLICY