StudentShare

Our website is a unique platform where students can share their papers in a matter of giving an example of the work to be done. If you find papers

matching your topic, you may use them only as an example of work. This is 100% legal. You may not submit downloaded papers as your own, that is cheating. Also you

should remember, that this work was alredy submitted once by a student who originally wrote it.

Login

Create an Account

The service is 100% legal

- Home

- Free Samples

- Premium Essays

- Editing Services

- Extra Tools

- Essay Writing Help

- About Us

✕

- Studentshare

- Subjects

- Engineering and Construction

- Quality Management Plan for the Aubin Station Project

Free

Quality Management Plan for the Aubin Station Project - Outline Example

Summary

The paper "Quality Management Plan for the Aubin Station Project" states that the contractor or the subcontractors shall be liable to the project specification compliance malfunctions. In addition, the contractor of the sub-contractors will be required to communicate to the quality control manager,…

Download full paper File format: .doc, available for editing

GRAB THE BEST PAPER96% of users find it useful

- Subject: Engineering and Construction

- Type: Outline

- Level: Undergraduate

- Pages: 4 (1000 words)

- Downloads: 0

- Author: riley26

Extract of sample "Quality Management Plan for the Aubin Station Project"

Quality Management Introduction Plans are underway to implement the quality management plan (QMP) for the Aubin station project. The implementation will ensure that all project packages are in compliance with the provisions in the contact. Measures of quality control will include sampling protocols documenting, administering quality control operation of all parties to the contact and many others. Essentially, the quality management plan will be guided by the Australian contracting policies and construction industry contract necessities.

The construction process will be supervised by the quality control manager (QCM). The quality control manager will have the mandate and duty to align the construction work to meet the conditions of the contract. The quality control manager may choose to have an engineer to assist him in assessing site activities. The firm entrusted with the responsibility to test project compliance issues must act in accordance with work requirements as outlined in the contract. The results gathered by the testing firm should be forwarded to the quality control manager for assessment. In case of any nonconformities regarding the contract specifications, the quality control manger should contact the project manager on the site. In essence, all engineering ethical standards must be adhered to. In addition, the laws relating to construction in the country must be followed to eliminate malpractices in the construction process.

1.1 Project Organization

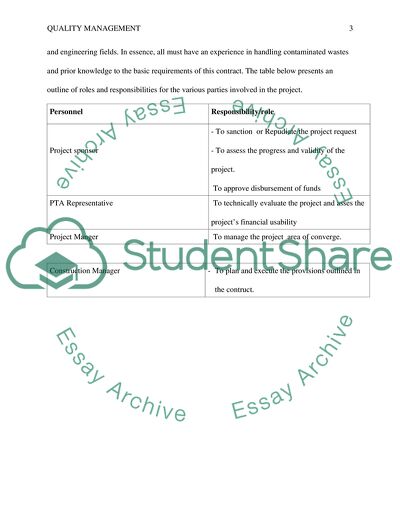

The contractor and the subcontractors must possess distinguished professional skills. In addition, the contractor and subcontractors must have substantial experience in the construction and engineering fields. In essence, all must have an experience in handling contaminated wastes and prior knowledge to the basic requirements of this contract. The table below presents an outline of roles and responsibilities for the various parties involved in the project.

Personnel

Responsibility/role

Project sponsor

- To sanction or Repudiate the project request

- To assess the progress and validity of the project.

To approve disbursement of funds

PTA Representative

To technically evaluate the project and asses the project’s financial usability

Project Manger

To manage the project area of converge.

Construction Manager

To plan and execute the provisions outlined in the contruct.

Quality Control Manager

To document progress of the project and conduct field checkups.

To give a daily report of the progress of the project.

To assess and certify project submittals.

To keep a register for daily reports submitted by the field officer.

Safety and Health Officer

To coordinate health safety program during the execution of the project.

To provide safety guidelines and reporting health related challenges to the quality control manager

Superintendent

General supervision of field activities.

Maintenance of the construction equipment and other necessaries.

2.1 Implementation

The implémentation responsibility will be asigned to the quality control manager (QCM). In this regard, the QCM must ensure that the supplies to the project are of standard quality and all the tools required are provided. Quality is a key consideration for any profession and, therefore, all preliquisites for the construction project must be fulfilled. The quality control management shall report directly to the on-site manager. In addition the quality control manager shall coduct daily inspection on the construction site to ascertain that the required quality standards have been maintained. Consequently, the QCM shall compile a daily report and submit it to the transport manager in order to facilitate transportation plans.

The daily report submitted by the various organs shall be compiled and analysed weekly to monitor the general progress of the project. All the personnel involved in ensuring the success of the project shall merge their reports on weekly basis to analysis the progress and solve any challenges that may arise. In addition, all the officers shall have requalr meetings to ensure that the work progress goes hand in hand with the provisions in the contract. It is imperative to recognize that violation of the terms and condation of the contarct can result into huge losses in terms of time and resources. The law provides that the person contracting to provide services to another shall meet all the expenses in case there is a breach of contract.

3.1 Documeting

The quality control manager will document all the records submitted to him by the officers on the ground. All documents are to be keep in a save place where they can be obtained on request, The documenting process should be flexible and clear to give room for changes that may arise in the course of persuing the contract. Daily activities such as site inspection remarks, material testing results and challeges exeprienced during operations in the field should be recorded and savely documented on daily basis. The quality control manager will ensure that the documented information is on save hands and can be accessed anytime.

4.1 Inspections

Daily inspection of the activities going on in the field is required The quality conrol manger will collude with the subcontracts to organize how the inspection process will be conducted. The QCM, in conjuction with sub-contactors and other personnel, shall undertake the site inspection phases discussed below for the entire project.

Phase 1 : Inspection before commencement of the project

The inspection at this phase will involve a review of the contractual terms and an assesment of the construction tools and equipment. In addition an evaluation of the construction site will be done to identify whether all the preliminary construction requirements have been meet. Finally, an assesment of possible challenges will be done to facilitate development of effective mitigtion strategies.

Phase 2 : Inspection after commencement of the construction.

Once the construction work has began, regular checkups will be conducted to ensure the projects is in complince with the contractual terms aand requirements. In this inspection phase, assessement of quality workmanship is done. Additonally, a review of control testing is done to ensure that it is in line with control requirements. Essentially defective and damaged materials are identified at this inspection phase.

Phase 3 : Quality Control

This will involve daily follow up activites to assess all the players involved in the contraction process. Quality control manager will ensure that the project progress is in line with contractual requirements and other aspects such as the guidelines of the Austalian test methods. Field testing will be conducted under the instructions of quality cotrol manager. The people assigned to cnduct field testing will be required to follow the prescribed test parametres In addition, they will be required to verify that the test equipment to be used in the field are working.

The findings collected every day will be documented on the daily quality control report. Inspection forms as presented in Appendix B. Any issues regarding deviation from the stated requirements should be forwarded to the quality control manager to facilitate taking of the appropriate course of action. Both the contractor and subcontractors shall apply their engineering skills to identify errors and the causes of those errors. The information to be recorded on the daily quality control report include:

Numbers of personnel involved.

Weather conditions.

Forms and number of tests performed.

Test results.

Challenges experienced.

Proposed course of action.

Guidelines received from the engineer.

Health and Safety issues

Finally the contractor or the subcontractors shall be liable to the project specification compliance malfunctions. In addition, the contractor of the sub-contractors will be required to communicate to the quality control manager in case of any challenges.

SPONSOR ACCEPTANCE

Approved by the project sponsor:

Date

Read

More

sponsored ads

Save Your Time for More Important Things

Let us write or edit the outline on your topic

"Quality Management Plan for the Aubin Station Project"

with a personal 20% discount.

GRAB THE BEST PAPER

✕

- TERMS & CONDITIONS

- PRIVACY POLICY

- COOKIES POLICY