StudentShare

Our website is a unique platform where students can share their papers in a matter of giving an example of the work to be done. If you find papers

matching your topic, you may use them only as an example of work. This is 100% legal. You may not submit downloaded papers as your own, that is cheating. Also you

should remember, that this work was alredy submitted once by a student who originally wrote it.

Login

Create an Account

The service is 100% legal

- Home

- Free Samples

- Premium Essays

- Editing Services

- Extra Tools

- Essay Writing Help

- About Us

✕

- Studentshare

- Subjects

- Engineering and Construction

- Material Requirement Planning

Free

Material Requirement Planning - Report Example

Summary

The paper "Material Requirement Planning" describes that inventory status records keep details of net materials present for current use as stock at hand and ordered materials from suppliers. Bills of materials show details of the materials and sub-assemblies needed to manufacture each product…

Download full paper File format: .doc, available for editing

GRAB THE BEST PAPER96.4% of users find it useful

- Subject: Engineering and Construction

- Type: Report

- Level: Masters

- Pages: 4 (1000 words)

- Downloads: 0

- Author: nicklaus24

Extract of sample "Material Requirement Planning"

Material Requirement Planning Lecturer: Demand Management Concept The elementary role of Materials Requirement Planning (MRP) system comprises inventory control, processing of bill of materials and fundamental scheduling. MRP assists institutions to sustain lower inventory levels. It helps in planning of manufacturing, procurement and distribution activities. Manufacturing companies, irrespective of their products, encounter similar daily real problems. Customers desire products to be availed in a shorter time as compared to the time taken in manufacturing. Therefore, some level of planning is needed. Companies ought to control the types and amount of materials they buy, plan the products to be produced and in what amounts. It should be ensured products meet existing and future consumer demand. This should be made possible at the lowest cost (Drexl & Kimms, 2008). A bad decision made concerning this areas results in the company losing a lot of money. For instance, when a company buys inadequate quantities of an item to be used in manufacturing, it may be short of meeting contract responsibilities to avail timely products. Again, a company buying excessive numbers of an item, wastes money. The quantity in excess ties up the cash though it remains as stock and cannot be used again. Starting production of an order on a wrong footing i.e. wrong timing causes client deadlines to go unobserved.

Case #1

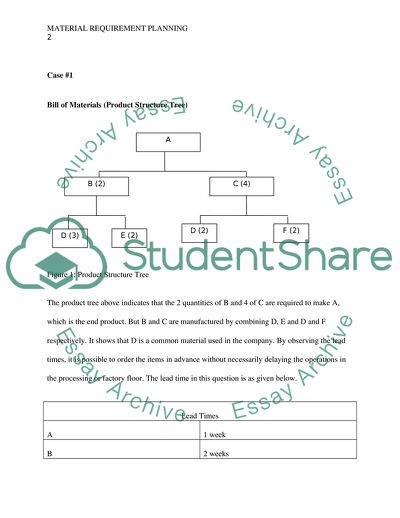

Bill of Materials (Product Structure Tree)

Figure 1: Product Structure Tree

The product tree above indicates that the 2 quantities of B and 4 of C are required to make A, which is the end product. But B and C are manufactured by combining D, E and D and F respectively. It shows that D is a common material used in the company. By observing the lead times, it is possible to order the items in advance without necessarily delaying the operations in the processing or factory floor. The lead time in this question is as given below.

Lead Times

A

1 week

B

2 weeks

C

2 weeks

D

2 weeks

E

3 weeks

F

3 weeks

Table 1: Lead times, week 10 requires 100 units of A

Lead times of the final product are usually short because nearly all the constituent parts have been brought and probably require internal production mix to bring out the ultimate product.

To start with, the quantity of units of A assumes a backward schedule so as to permit their lead time. Therefore, in the materials requirement plan shown below, 100 units of A have to placed an order in the 9th week for them to be received by the 10th week. Required quantities will be marked in week 10 but order placement will be done in week 9 and marked as 100 in week 9. The lead time (LT) will be one week.

Week

1

2

3

4

5

6

7

8

9

10

A

Required

100

Order placement

100

Table 2: Lead times for end product A

LT= 1 week

Consequently, scheduling starts with the elements making up A. In the situation of element B, there are required 2 B’s for each A. Ordinarily 100 A’s are need, that infers 200 B’s. Likewise, the schedule is backed up for the necessary 2 weeks of lead time. The lead times are pushed backwards depending on the amount of lead time allocated. In the nut shell, the required time of placement is slightly earlier than the required time.

Week

1

2

3

4

5

6

7

8

9

10

A

Required

100

Order placement

100

B

Required

200

Order placement

200

Table 3: component A and B requirement placements

Ultimately, a repeat of the process for all elements, gives the eventual materials requirements plan. The table will show when individual items are required and when the need to be placed. This ensures that the time it takes to be delivered to the company floor is within the lead time. No disruptions on the operational cycle if the items or raw materials are ordered in good time. The table exhibits a diagonal shape indicating that items F and E needs to be procured in advance so that the procedure of making successive items are in the right track. Materials resource planning will have captured the aspect of time, cost and convenience to production activities. Delay in delivery of these items infers a delay in production and therefore customer quality is compromised.

Week

1

2

3

4

5

6

7

8

9

10

A

LT=1

Required

100

Order placement

100

B

LT=2

Required

200

Order placement

200

C

LT=2

Required

400

Order placement

400

D

LT=2

Required

200

300

Order placement

200

300

E

LT=3

Required

200

Order placement

200

F

LT=3

Required

200

Order placement

200

Table 4: Materials Requirement Planning Chart

Techniques and Practices of Inventory Management

The master production schedule is basically a time plan for phasing and specifying how many and the time the firm intends to build on each item. It borrows on aggregate plan and specific end items. MRP is a technique and tool to solve these problems. It gives answers for a range of questions like items required, quantity demanded and possible time of delivery (Toomey, 2006). MRP can be used both to products that are bought from external suppliers and to sub-assembly lines, made internally, that are elements of sophisticated items. From the calculations above the data considered the end item(s) being manufactured. This at times is referred to as Independent Demand, or category (0) on Bill of materials (BOM). It points out the time required, and when the quantities will be delivered to meet the demand. It indicates the shelf life of materials in storage. Besides, inventory status records keep details of net materials present for current use as stock at hand and ordered materials from suppliers. Bills of materials shows details of the materials, elements and sub-assemblies needed to manufacture each product. Planning data involves all the constraints and directions to make the end items (Cheng & Podolsky, 2004). This comprises such issues as: routings, standards on machine and labor, standards on quality and testing, commands regarding pull and push, lot sizing procedures like size fixed lot, economic order quantity (EOQ), percentages of scrap, and other input materials.

References

Cheng, T. C., & Podolsky, C. (2004). Just-in-Time Manufacturing: An introduction. Springer.

Drexl, A., & Kimms, A. (2008). Beyond Manufacturing Resource Planning (MRP II): Advanced Models and Methods for Production Planning. Springer.

Toomey, J. W. (2006). MRP II: Planning for manufacturing excellence. Springer.

Read

More

sponsored ads

Save Your Time for More Important Things

Let us write or edit the report on your topic

"Material Requirement Planning"

with a personal 20% discount.

GRAB THE BEST PAPER

✕

- TERMS & CONDITIONS

- PRIVACY POLICY

- COOKIES POLICY